-

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more.

SingaporeIt is really a pleasure cooperation. You are fast understanding and knowlegeable, also your Check valves worked well. We believe that we will have a great chance to cooperate more. -

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team!

ItalyTks for your consisent support for more than 10 years. Your diligence, professional technical support and rich experience in the pipeline projects has biggly help the business between us. Together we will win more and more tenders in the future. Best Regards to you and your team, and finally Come on DEYE Piping team! -

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business.

EgyptYou are honnesty and very reliable parnter, tks for your support on the technical data sheets and addtional works to fast the delivery time. Your professional answers are always impressed. also Your products are beautiful. We apprecite all the offorts you have done for the years business. -

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs.

UAEYou are Excellent, especially the quanlity control step by step, We've got all the photos and videos we want. and the documents we received all meet the request. Our boss is very Satisfied and he said he will give you more orders. We like your professional and fast jobs. -

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend.

PeruThe mould you opened for the valve are good, the new types of butterfly valves is popular. It will biggly increase the business between us. Tks for your suggestions on the flange holes. The valves are in good finishing and well packaged when we received them. Thank you, my friend. -

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

KazakhstanThe end user is safisfied with your A234WPB fittings and A105 Flanges, the have finished the welding at present, all works well.Tks for your professional suggestions and the operation manual. We also won the 2nd Phase job, we have sent to you this morning, Pls confirm all the specifications to proceed.

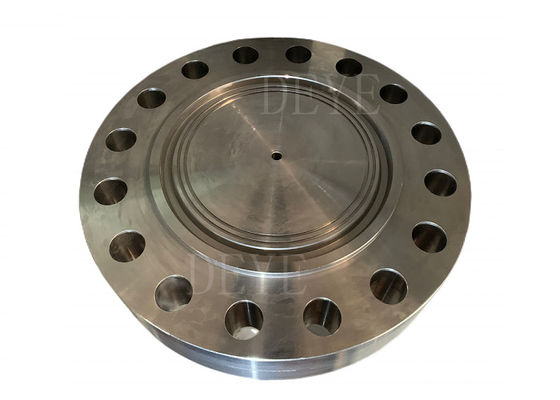

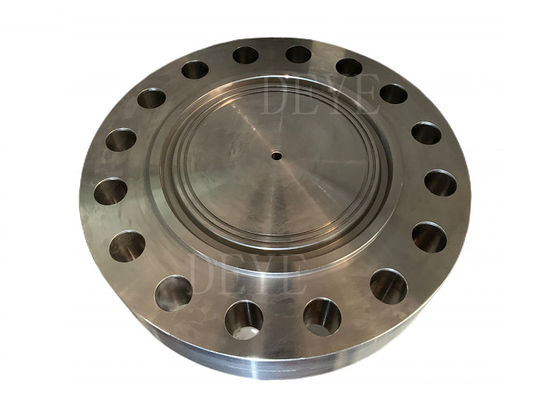

High Pressure Forged Steel Flange 900lbs 1500lbs A105 With RTJ Face

| Place of Origin | CHINA |

|---|---|

| Brand Name | DEYE |

| Certification | ISO9001:2015 PED |

| Model Number | PF-FL-BL16 |

| Document | Product Brochure PDF |

| Minimum Order Quantity | 10PCS |

| Price | USD10-USD100 each pcs |

| Packaging Details | Fumigation Ply-wooden cases |

| Delivery Time | 30 days for usual order |

| Payment Terms | T/T, L/C, D/P |

| Standard | ASME B16.5, ASME B16.47, API 6A, EN 1092-1, BS 4504, BS 10, DIN, JIS, GOST. | Material | A105, A105N, A350LF2, A182F22, F11, F56, F60, Stainless Steel |

|---|---|---|---|

| Size | 1/2"(DN15)-88"(DN2200) | Types | Weld Neck, Slip On, Blind, Socket Weld, Threaded, Lap Joint, Spectacle, Paddle, Long Weld Neck, Spacer, Orifice, Reduced, Plate. |

| Pressure Rating | Class 150, 300, 400, 600, 900, 1500, 2500; PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400. | Surface | Black,Golden Yellow, Cold Galvanized, HDG. Anti-Rust Oil |

| Highlight | High Pressure Forged Steel Flange,Forged Steel Flange 900lbs,A105 steel flanges |

||

High Pressure 900lbs 1500lbs A105 Steel Flanges With RTJ Face

The Class 1500 Lb Flange, 900LBS Flanges Dimensions allow the flanges to hold 1500lbs/900LBS of force, It is equal to 250Bar /150Bar. they are the high pressure capable flanges. There are different types of flanges can bear the high pressure design includes slip on flanges, blind flanges, weld neck flanges, socket welded flanges and threaded flanges. the sealing Design of the high pressure 900LBS 1500LBS flanges are mostly with RTJ, which is basically a machined metallic ring having a deep groove cut into its face Metallic RTJ gaskets sit in the groove to seal the flange pair. When the connecting bolts of the RTJ flanges are tightened, the gasket is compressed and the flange pair creates a leak-proof tight seal. The high Pressure flanges are widly used in oil field valves, pipework assemblies, refineries, high-integrity pressure vessel joints,

chemical and petrochemical plants, etc

Product Information/Product Description/Basis Information/Specification

| Product Name | HIGH PRESSURE 900LBS 1500LBS A105 STEEL FLANGES WITH RTJ FACE | |

| Types | Plate, Welding Neck, Slip on, Blind, Lap joint, Threaded Flange ,socket welding, Long weld neck, Loose Flanges,, Orifice, Blinds, customized, | |

| Face Finish | RFlat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) | |

| Standard | ANSI | ANSI B16.5 ASME B16.47 series A/B, API605, AWWAC207 |

| DIN | DIN 2631 DIN2632 DIN2543 DIN2502 2573 2527 2565 DIN2566 DIN 2641,2642, | |

| GOST | GOST 12820-80,GOST 12821-80,Gost Blind | |

| EN | EN1092-1:2002 | |

| JIS | JIS B2220-2004, KS D3576, KS B6216,KS B1511-2007,JIS B2261; JIS B8210 | |

| BS | BS4504,BS10 Table D/E | |

| UNI | UNI 2253-67,UNI6091-67,UNI2276-67,UNI2280-67,UNI6089-67 | |

| SABS | SABS 1123 | |

| Material | ANSI | CS A105/SA 105N |

| Steels for Low Temperature Service: A 350 Grade LF 1, A350LF2, A350LF4, A350LF6, A350LF8. CL1/CL2, LF3 CL1/CL2, | ||

| Stainless Steel SS 304/304L,316/316L, SS321, SS347H, SS316TI, SS304HM SS316H, 904L, UNS31803, UNS32750, UNS32760 | ||

| Alloy Steel: WHPY45/52/65/80/A 182 Grade F 5, A 182 Grade F 9, A 182 Grade F 11, F 12, F22, F91, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), | ||

| DIN | CS RST37.2;S235JR SS 304/304L,316/316L, Stainless steel 1.4301, 1.4404, SAF2205, SAF2507, | |

| GOST | CS CT20;16MN;SS 304/304L,316/316L | |

| EN | CS RST37.2;S235JR;C22.8SS 304/304L,316/316L | |

| JIS | CS SS400,SF440,SS 304/304L, 316/316L | |

| BS | CSRST37.2;S235JR;C22.8;Q235SS 304/304L,316/316L | |

| UNI | CSRST37.2;S235JR;C22.8;Q235SS 304/304L,316/316L | |

| SABS | CSRST37.2;S235JR;Q235;SS 304/304L,316/316L | |

| Pressure | ANSI | Class 150, 300, 600, 900, 1500 2500lbs, with welded thickness of STD, SCH40, SCH80, SCH160. SCHXXS |

| DIN | PN6,PN10,PN16,PN25,PN40,PN64,PN100 | |

| GOST | PN6,PN10,PN16,PN25 | |

| EN | PN6,PN10,PN16,PN25,PN40,PN64,PN100 | |

| JIS | 1K,2K,5K,10K,16K,20K,30K,40K | |

| BS | PN6,PN10,PN16,PN25,PN40,PN64,PN100 | |

| UNI | PN6,PN10,PN16,PN25,PN40 | |

| SABS | 600KPA,1000,1600,2500,4000 | |

| Size | ANSI | 1/2” – 60” |

| DIN | DN15-DN2000 | |

| GOST | DN10-DN1600 | |

| EN | DN15-DN2000 | |

| JIS | 15A-1500A | |

| BS | DN15-DN2000 | |

| UNI | DN10-DN2000 | |

| SABS | DN10-DN600 | |

| Surface | Oil Black Paint, varnish, Golden yellow paint, anti-rust oil, galvanizing, Cold and Hot Dip Galvanized etc, Zinc plating. chrome plating. Black treatment, anodize, powder coating. punishment, brass plating. etc. | |

Features /Characteristics

•Carbon steel flanges shall not be used in services above 425 °C

•High-temperature service: Standard carbon steel material shall be ASTM A 105, a material that can be safely

used for temperatures between minus 29 °C and 425 °C.

•Low-temperature Service: Carbon steel flanges used for services below minus 29 °C, shall conform to the

impact-testing requirements of ASME B 31.3.

•ASTM A 350-LF2 shall be the standard material for low temperature applications

•High-Yield Service: High strength carbon steel flanges ASTM A694 should fit API Std. 5L

pipe Grade X42 to X65.

•Material for low-alloy steel flanges (11/4 Cr – 1/2 Mo) shall be ASTM A 182-F11. Material for

intermediate alloy steel flanges (11/2 Cr – 5 Mo) shall be ASTM A 182-F5.

Technology/ How to use and install the different flange types

WELDING NECK FLANGES

They are connected to the pipe by means of a Butt weld connection. They are

used when X-ray testing is required or if the torque over unions are maximum.

Its long tapered neck optimizes the stress distribution.

![]()

SLIP-ON FLANGES

This kind of flanges are installed with two weld bead, sliding the pipe inside.

Thus installation costs are lower, so less accuracy is required for pipe cutting.

![]()

THREADED FLANGES

They are usually installed with the pipe previously threaded, in places where

welding cannot be done. We do not recommend to install if there are high

pressure variations in the system

![]()

LAP JOINT FLANGES

They slide on an overlapped gasket. They are commonly used where it is

necessary to dismantle in order to be cleaned or repaired. Dismantling cost

decreases due to the ease of flange turning and drilling alignment.

.![]()

SOCKET WELD FLANGES

This kind of flange is especially designed for lower small diameters and high

pressures. The pipe is inserted into the flange up to the seat and then is fillet

welded against the cube.

![]()

BLIND FLANGES

Blind flanges are utilized for pipe ends, and they bolted to any of the above

flange types.

![]()

Material Grades:

| ASTM Designatioin |

Tensile strength | Fluency limit Elongation in 50 mm. | Stress | Brinell | Charpy - V | |||||||

| Hardness (HB) |

Energy J | Testing Temp. ºC | ||||||||||

| Ksi min. | MPa | Ksi min. | MPa | % min. | % min. | Min. 1 Test tube |

Average 3 Test tubes |

|||||

| A105 - 05 | ||||||||||||

| 70 | 485 | 36 | 250 | 22 | 30 | 187 max. | ||||||

| A182 - 07 | ||||||||||||

| Grades | F1 | 70 | 485 | 40 | 275 | 20 | 30 | 143 - 192 | ||||

| F5 | 70 | 485 | 40 | 275 | 20 | 35 | 143 - 217 | |||||

| F11 Cl. 1 | 60 | 415 | 30 | 205 | 20 | 45 | 121 - 174 | |||||

| F11 Cl. 2 | 70 | 485 | 40 | 275 | 20 | 30 | 143 - 207 | |||||

| F11 Cl. 3 | 75 | 515 | 45 | 310 | 20 | 30 | 156 - 207 | |||||

| F22 Cl. 1 | 60 | 415 | 30 | 205 | 20 | 35 | 170 max. | |||||

| F22 Cl. 3 | 75 | 515 | 45 | 310 | 20 | 30 | ||||||

| F304 | 751 | 5151 | 30 | 205 | 30 | 50 | 156 - 207 | |||||

| F304L | 702 | 4852 | 25 | 170 | 30 | 50 | ||||||

| F316 | 751 | 5151 | 30 | 205 | 30 | 50 | ||||||

| F316L | 702 | 4852 | 25 | 170 | 30 | 50 | ||||||

| F321 | 751 | 5151 | 30 | 205 | 30 | 50 | ||||||

| A350 - 04 | ||||||||||||

| Grades | LF1 LF2 Cl. 1 LF2 Cl. 2 |

60 - 85 70 - 95 70 - 95 |

415 - 585 485 - 655 485 - 655 |

30 36 36 |

3 4 3 4 3 4 |

205 250 250 |

25 22 22 |

38 30 30 |

197 max. 197 max. 197 max. |

14 16 20 |

18 20 27 |

-29 -46 -18 |

| LF3 Cl. 1 | 70 - 95 | 485 - 655 | 37.5 3 4 | 260 | 22 | 35 | 197 max. | 16 | 20 | -101 | ||

| LF3 Cl. 2 | 70 - 95 | 485 - 655 | 37.5 3 4 | 260 | 22 | 35 | 197 max. | 20 | 27 | -101 | ||

| A694 - 03 | ||||||||||||

| Grades | F42 | 60 | 415 | 42 | 290 | 20 | ||||||

| F52 | 66 | 455 | 52 | 360 | 20 | |||||||

| F56 | 68 | 470 | 56 | 385 | 20 | |||||||

| F60 | 75 | 515 | 60 | 415 | 20 | |||||||

| F65 | 77 | 530 | 65 | 450 | 20 | |||||||

| F70 | 82 | 565 | 70 | 485 | 18 | |||||||

Production Process

![]()

Flanged Standard

ASME B16.5

This is the most used flange standard worldwide. The standard includes

forged, cast and laminated flanges. It covers service, materials, dimensions,

tolerances, marking and testing for flanges. It also describes all flange types

for size 1/2”to 24”Class 150#, 300#, 400#, 600#, 900# & 1500#, and 1/2”to

12”Class 2500#.

ASME B16.36

This standard is applicable to flanges for flow measurement with orifice plate.

ASME B16.36 flanges have the same dimensions as B16.5 flanges except for the minimum thickness

that is increased to allow measurement orifices.

Moreover, two slots and bolts allow flange separation and the replacement of

the measurement plate. It covers sizes from 1”to 24”Class 300# to 1500#,

and sizes 1”to 12”Class 2500#.

MSS SP-44

An standardization used for thin thicknesses and high strength. It covers

ranges from 12”to 60”Class 150# to 600# and up to 48”Class 900# only

for blind and welding neck flanges. Outside diameter and drilling template

matches with ASME up to 36. Therefore, they can be used with valves and

pumps according to ASME.

ASME B16.47

This standard covers the previous one complementing it with materials,

pressure ratings and temperatures from ASME B16.5. A type class is similar to

MSS-SP44. B type is the same as API 605.

ASME B16.20

It includes materials, dimensions and marking of rings for steel flanges 1/2 to

24”Class 150# to 1500#, and 36”Class 900#.

API 6 A

API 6 A specification has been created for wellheads and Christmas trees.

It includes the standardization of lap joint flanges, which are dimensionally

replaceable with ASME B16.5 ones but adding some tolerances with all sizes.

However, as API materials are more resistant, the maximum service pressure of

API/ASME union is limited to that of lower performance flange.

EN1092-1

This European Standard for a single series of flanges specifies requirements for circular steel

flanges in PN designations PN 2,5 to PN 400 and nominal sizes from DN 10 to DN 4000.

This European Standard specifies the flange types and their facings, dimensions, tolerances,

threading, bolt sizes, flange jointing face surface finish, marking, materials, pressure/ temperature

ratings and approximate flange masses.

For the purpose of this European Standard, "flanges" include also lapped ends and collars.

This European Standard applies to flanges manufactured in accordance with the methods

described in Table 1. Non-gasketed pipe joints are outside the scope of this European Standard.

Application/Usage

A flange is a method of connecting pipes, valves, pumps, and other equipment to form a piping

system to convey the water, steam, air, gas and oil. It also provides easy access for cleaning,

inspection, or modification.